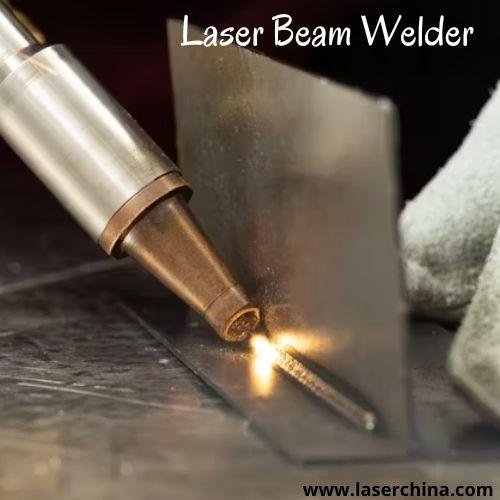

When considering modern welding technologies, the laser beam welder has become increasingly significant in industrial manufacturing. This tool relies on the focused energy of a laser to fuse materials, primarily metals, at the molecular level. Unlike traditional welding methods that involve melting larger areas, a laser beam welder can deliver highly concentrated energy precisely where it is required. This capability raises the question of whether it can truly balance the needs for both precision and speed in a manufacturing environment, and the answer lies in understanding the principles, applications, and operational nuances of the technology.

At its core, a laser beam welder operates by emitting a highly concentrated light beam that is absorbed by the target material, causing it to heat rapidly and form a weld. The process is not only highly controlled but also allows for extremely narrow and deep welds, which traditional arc welding or resistance welding methods might struggle to achieve. The ability to focus energy precisely means that even very thin or delicate materials can be joined without causing significant distortion. This is particularly important in industries such as automotive, aerospace, and electronics, where the structural integrity and dimensional accuracy of parts are critical.

Speed, on the other hand, is a factor often associated with throughput and efficiency. In manufacturing lines where large numbers of components need welding, traditional methods can be slower due to the requirement for preheating, electrode changes, and the overall slower energy transfer. A laser beam welder addresses this by delivering energy in an almost instantaneous fashion. The laser does not need to make contact with the material, and because it can move rapidly along programmed paths, production speed can be significantly higher. Moreover, automation of laser welding systems ensures consistent quality at high speeds, reducing the need for repeated adjustments and human intervention.

The synergy between precision and speed is achieved through careful control of laser parameters such as power, pulse duration, and focus. For instance, pulsed lasers can deliver bursts of energy that allow for precise spot welding without overheating surrounding areas. Continuous-wave lasers, on the other hand, can create longer weld seams efficiently. Advanced control software allows operators to adjust these parameters in real-time to meet specific material requirements, weld thicknesses, and desired joint characteristics. This flexibility makes it possible to maintain high accuracy without compromising production rates.

One remarkable aspect of the laser beam welder is its adaptability to complex geometries and challenging materials. Metals that are traditionally difficult to weld, such as stainless steel, aluminum alloys, and titanium, can be handled effectively with laser technology. Furthermore, the ability to weld very fine components, such as those used in microelectronics or medical devices, demonstrates how precision is not lost even when dealing with extremely small or intricate parts. At the same time, larger industrial components, such as automotive body panels or structural frames, can be processed efficiently, showcasing the technology’s range.

In addition to its operational benefits, the laser beam welder contributes to manufacturing quality and consistency. Because the energy is so concentrated, the heat-affected zone around the weld is minimized. This reduction in thermal distortion translates to less post-weld finishing and more predictable results, which is essential for high-volume production environments. Automation and robotic integration further amplify the speed and consistency, as robotic arms equipped with laser welders can operate continuously without fatigue, ensuring that each weld meets the same standards.

Applications of laser beam welding are broad and varied. In the automotive sector, the technology is used to assemble car body parts with a combination of high precision and rapid processing, which is vital to meet production timelines. In aerospace, where material integrity and weight reduction are critical, laser welding allows for the joining of lightweight alloys with minimal structural compromise. Electronics manufacturers rely on laser beam welders for micro-welding tasks, joining components too small or delicate for traditional welding methods. Even in medical device production, laser welders are employed to ensure the strength and precision of surgical instruments or implants.

Safety and operational considerations are also key to understanding the effectiveness of laser beam welders. Unlike traditional arc welding, the process generates less spatter, reducing the need for extensive cleanup. Protective measures, such as specialized enclosures and laser shielding, ensure safe operation in industrial settings. Operators are trained to manage beam alignment, focus adjustments, and system calibration, which reinforces both precision and operational speed without compromising safety standards.

Training and integration into manufacturing processes further enhance the performance of laser beam welders. Operators and engineers who understand the nuances of laser-material interaction can optimize the system to achieve desired results efficiently. Simulation software and process monitoring allow manufacturers to predict weld outcomes before actual production, saving time and materials. The combination of technology, skill, and process control ensures that a laser beam welder can deliver both precise welds and fast throughput.

In terms of long-term industrial impact, laser beam welding is positioned as a transformative technology. Its ability to handle diverse materials and complex designs with both speed and precision makes it indispensable in modern manufacturing. As industries push for higher efficiency, lower production costs, and superior quality, the laser beam welder continues to demonstrate that it can meet these demands without the trade-offs traditionally associated with conventional welding methods.

In conclusion, the laser beam welder exemplifies how modern technology can bridge the gap between precision and speed. Its focused energy, automation potential, adaptability to different materials, and ability to integrate seamlessly into industrial processes make it a cornerstone of contemporary manufacturing. The careful control of laser parameters, combined with skilled operation and system integration, ensures that both fine details and large-scale production goals are achievable simultaneously. For industries where quality, speed, and reliability are paramount, the laser beam welder represents a solution that effectively balances these often competing demands.

Final Thoughts

The laser beam welder is more than a tool; it’s a versatile technology that redefines how industrial welding is approached. By offering precision without compromising speed, it meets the rigorous demands of modern manufacturing while providing consistent and reliable results. Its adaptability across materials, sizes, and industrial sectors ensures that it will continue to play a vital role in shaping efficient and high-quality production lines. Manufacturers that leverage this technology effectively are able to achieve operational excellence, demonstrating that precision and efficiency can coexist in the same process.